FOXWATER’s team of specialists is prepared to work in different industrial sectors, offering sustainability solutions combined with the most modern technologies.

The FOXWATER team has already designed and implemented services for sectors such as:

Steel industry; Paper And Cellulose; Gas and Oil; food and drinks; Agribusiness; Cosmetic and Pharmaceutical.

Desalination

Water is vital. Despite being abundant, it is almost entirely salty and, therefore, unfit for human consumption, animals and USE IN AGRICULTURE.

To reverse this situation, FOXWATER offers the desalination of sea or brackish water. They are modular solutions that make it possible to scale according to the needs of the project.

Desalination systems include:

Automatic filtration: it is a self-cleaning system that offers a filtration solution for water with a high level of suspended solids.

Reverse osmosis: in this process water passes under pressure through membranes removing salts and impurities. This process achieves high productivity, around 99% waste reduction.

FOXWATER also offers mobile Desalination or Ultrafiltration units for industrial or military purposes. These units operate in brackish and surface waters.

Wastewater treatment

FOXWATER designs, installs and operates modular effluent treatment stations for different industrial sectors .

It is a customized solution that offers flexibility and adaptation to pre-existing systems and the space where it will be installed. In addition, it facilitates maintenance and expansion, when necessary.

Using the BOO Built, Own, Operate business modality , FOXWATER meets the needs of its customers in all phases of the effluent treatment plant: design, construction and operation.

landfill percolate

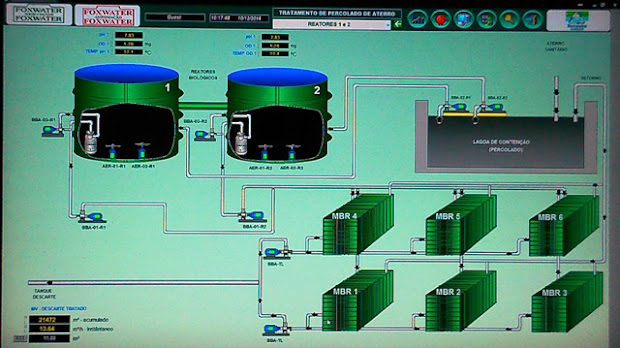

FOXWATER ‘s flagship is the treatment of landfill leachate, also known as leachate.

It is a liquid with a strong odor generated by the decomposition of organic and inorganic waste deposited in landfills. It is a highly polluting waste that needs proper treatment.

With modular and customized projects, FOXWATER performs this treatment of leachate from the sanitary landfill with MBR technology, which meets the specifications of Brazilian environmental legislation.

This allows for the optimization of operating costs and treatment processes, which accompany the growth of the landfill, as well as correctly disposing of waste and, when permitted, reusing the treated liquid.

reused water

One of the key points in water management is reused water, as it indicates the company’s commitment to sustainability.

FOXWATER offers customized solutions for reuse systems so that the project reaches the quality required and demanded by the legislation, guaranteeing adequate disinfection and safety of the effluent .

Among the main applications for reuse water are cooling and steam; use in industrial processes, irrigation of gardens and agricultural areas not intended for human consumption and washing of external areas.

Sludge Dewatering

Sludge volume reduction, also called sludge dewatering, consists of removing a large amount of water from the sludge so that it can be transported and disposed of.

With this process, a significant reduction in sludge volume is obtained, optimizing transport costs and transport operation time.

Among the main applications are ponds or stabilization or equalization tanks, treatment systems, sludge consolidation tanks or biological reactors and river desilting.

FOXWATER ‘s technical team also works on collapsed systems, carrying out preventive maintenance, meeting specific demands.

Groundwater Decontamination

FOXWATER designs, installs and operates modular groundwater decontamination stations, evaluating agents and levels of pollution, to use the best technologies, which will guarantee water quality and environmental safety .

Main applications in polluting agents:

Pesticides and volatile halogenated organic compounds,

BTEX – aromatics and phenols in polluted groundwater;

Adsorbents of organohalogenates and refractory COD in infiltration waters;

Phenol in contaminated water from steel and chemical industries.

FOXWATER ETA and ETE automation

FOXWATER Automation automates industrial effluent and water treatment processes for industries, shops, condominiums, agribusiness, sanitation services, among others.

Monitoring of bodies of water is included in this activity.

By means of an Operational Control Center, remote monitoring is carried out, through sensors of various control parameters such as pH, TSS, Turbidity, etc. Property security equipment can be integrated, such as cameras, alarms and optical motion sensors. Monitoring can be made available on mobile systems such as cell phones, iPads and notebooks.

The automation system has solutions for:

Automatic adjustment of chlorine levels in drinking water reservoirs;

pH adjustment; Chlorination in capturing wells;

Automation of water treatment for consumption in boilers and cooling towers;

Automation of water treatment plant for supply including the parameters desired by the customer;

Automation of effluent treatment station for physical/chemical and biological process also including parameters required by legislation.

Operation and maintenance

FOXWATER in the O&M service modality – Operation and Maintenance – offers a complete range of solutions for its customers .

This includes operating, monitoring and maintenance services for installed projects, such as treatment systems.

Placing all its expertise at the service of customers, it allows them to remain aligned with their main activities, while FOXWATER enables reductions in operating costs, improvements in processes and productivity gains.

CTE – Effluent Treatment Center

Many companies, for different reasons, do not have an effluent treatment system, although they need to dispose of effluents to comply with environmental legislation.

To deal with these situations, FOXWATER ‘s solution is to implement a CTE close to the companies, to allocate the effluents to be treated and discarded, obeying the requirements of the legislation.

FOXWATER designs the CTE to serve companies with effluents with high complexity of contaminants, such as metals, oils and greases, organic load, phenol, organochlorines, BTEX .

Examples of this are the FOXWATER CTEs installed in Rio Grande do Sul and Rio de Janeiro, which can receive effluents from different sources for treatment.

CTF – FOXWATER Technological Center

FOXWATER TECHNOLOGICAL CENTER was developed to support, develop and nationalize different technologies available in the international market in order to keep the company in the “State of the Art” in the treatment of effluents.

CTF constantly seeks partnerships with Universities, Foundations and companies for development.