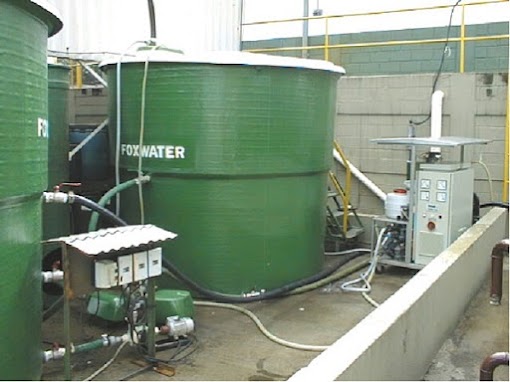

To meet the requirements of environmental agencies, obtain certifications and provide sustainable performance for its customers, FOXWATER offers different technologies for the treatment of water and industrial effluents, making environmental, economic and technical criteria compatible in its application.

Among the specific Technologies: Physical-Chemical Processes; Aerobic and Anaerobic Biological Processes; Biodigesters; MBR – (Membrane Bio Reactor); AOP – Advanced Oxidative Process; Microfiltration; Ultra Filtration; Nanofiltration; Reverse osmosis; Gas Exchange Membranes for Nitrogen etc.

Physical-Chemical System

Physical-chemical treatments constitute a set of processes aimed at reducing or, in some cases, eliminating those components of a residual flow of industrial origin, classified as contaminating or dangerous.

These systems can be physical-chemical methods or dissolved air flotation.

Physical-chemical methods

For each type of waste, adequate treatment is required, therefore, there are different physical-chemical methods.

The process is divided into coagulation, flocculation and decantation steps. Where chemical agents are added to form particles and finally promote the physical separation of molecules heavier than water, which will be removed and pressed.

dissolved air flotation

Also known as the FAD system, it is used for the separation of solid and liquid particles. It has the stages of coagulation and flocculation.

The physical separation occurs through the insufflation of dissolved air, adjusted to the particle sizes, increasing its thrust and causing it to rise.

Biological System

Aerobic and Anaerobic

Aerobic

The aerobic or activated sludge system is indicated for the treatment of industrial and domestic waste with organic load, providing outstanding quality of the treated effluent.

Its main objective is the reduction of solid and organic compounds in the treatment of effluents.

With a primary decanter, coarse suspended solids can be decanted. Then, the effluent goes to the biological reactor for aeration with aerators and diffusers. In this reactor, the sludge is separated and recirculated.

The secondary decanter is used to decant the sludge, recirculate it or send it to the sludge thickener for dewatering.

The excess sludge from the process can be pressed and sent to a landfill or another form of treatment provided for in environmental legislation.

The biological system is divided into the following stages:

Coarse and Fine Grading;

Equalization;

primary decanter

Aerobic or/and Anaerobic Biological Reactor;

Secondary decanter;

Sludge Denser or Sludge Pressing.

anaerobic

Applied together or separately with Aerobic systems and is usually applied in effluents with a higher organic load .

MBR

The “Membrane Bioreactor” or MBR technology was developed in the 1960s and uses selective or semipermeable membranes, which allow the filtration of effluents.

These membranes retain bacteria, viruses and solid contaminants, obtaining a high quality effluent that can be used in various operations and processes that do not require potable water.

Another gain with this technology is the reduced production of sludge, enabling a reduction in the operating costs of treatment and disposal.

Ammonia Nitrogen Removal

With technology developed by FOXWATER, the membrane process enables the separation of the NH3 compound (Ammonia).

Its application is focused on the treatment of water, effluents and slurry, where the membrane system contains Ammonia.

Ammoniacal nitrogen (NH3 -N) is a very common toxic pollutant, it originates from sewage waste, leachate from landfills, among others.

The presence of Ammoniacal Nitrogen is an indicator of pollution in natural sources, being used as a public health prevention measure, since its presence indicates contamination, and may cause intoxication if consumed.

The NH3 concentration is an important parameter to classify the water quality.

Among the techniques used to eliminate ammoniacal nitrogen are:

- Biological Removal by Nitrification and Denitrification

- Air Stripping Technology

- Electrodialysis (Ed)

- Adsorption

- Reverse osmosis

- chlorination

Reverse osmosis

As its name suggests, reverse osmosis is the reversal of the natural osmosis process.

It is a process in which water flows through a semipermeable membrane that blocks the passage of salts or other solutes through it.

This means that two liquids with different salt concentrations, stored in a container and separated only by a semipermeable membrane, tend to reach equilibrium (that is, tend to the same concentration of contaminants).

Reverse Electrodialysis – EDR

The EDR process consists of electrochemical separation with high recovery power and treatment of brackish water, with salt removal rates between 50 and 75%.

It uses the movement of ions to desalinate water. This technology requires less pretreatment than reverse osmosis, resulting in more reliable operations.

Among the main applications of reverse electrodialysis are the reuse of industrial effluents, especially from gas and oil extraction; polishing of captured water and desalination of groundwater.

Ultrafiltration

Ceramic Membranes and PVDF Membranes

Using ceramic membranes with special properties, FOXWATER ‘s Ultrafiltration systems offer greater resistance, durability and advantages in their applications. PVDF membranes offer higher Ultrafiltration flux and lower cost.

The Ultrafiltration system can be incorporated into MBR, ETA’s and ETE’s projects.

Ceramic membranes have distinct advantages over other materials:

- Asymmetric pore structure of membranes and special properties of ceramics;

- Resistance to high temperatures and temperature variations;

- Chemical resistance (pH variations 0 to 14) and abrasion;

- Automatic cleaning systems;

- Durability over 10 years.

Automatic Filtering

Having stainless steel screens of different sizes as filtering elements, FOXWATER ‘s automatic filtration process offers advantages over other processes.

With a self-cleaning system controlled by a timer or pressure variation, it ensures greater durability and allows high flow.

The main features are:

- Self-cleaning system controlled by pressure variation or controlled by a timer;

- Ability to treat liquids with problems causing obstruction;

- High flows with reduced area requirements;

- High durability.

Its application covers seawater filtration, cooling tower recirculation water protection, irrigation systems, potable water and protection of UF, EDR and RO membranes.

Advanced Oxidative Process

FOXWATER is a pioneer in Brazil in the use of the Advanced Oxidative Process – AOP – on an industrial scale, aiming at the removal and elimination of organic loads.

AOP, based on the generation of free radicals, enables the efficient degradation of various polluting compounds. Thus, it transforms the organic substances in the effluents into oxidized substances. This is possible with the application of ozone or hydrogen peroxide.

It is important to highlight that, for the effectiveness of the process, the choice of the substance with the highest oxidizing potential is decisive.

Applied in the treatment of groundwater and complex effluents, the POA has the following advantages:

– Process with high operational stability;

– Considered a clean process, where neither activated carbon nor sludge need to be removed after the procedure;

-Persistent pollutants or difficult to decompose biologically can be eliminated by wet oxidation.

BIOTECHNOLOGY CENTER

Created in 2015, FOXWATER ‘s Biotechnology Center aims to provide customers with the highest quality technological and sustainability solutions.

FOXWATER invests in research to increasingly improve products and processes for natural bioremediation, which is a safe and efficient process for the natural regeneration of contaminated ecosystems .

The technique uses natural microorganisms, such as bacteria, fungi, yeasts and enzymes capable of removing or neutralizing organic and inorganic pollutants present in soil and water.

With processes such as biostimulation and bioaugmentation, it is possible to optimize natural bioremediation and achieve national and international parameters for disposal in landfills or rivers, without any damage to biodiversity.

These technologies are known as the lowest cost solutions for the treatment of effluents, water and contaminated soils.

The FOXWATER Biotechnology Center works continuously and exhaustively on the selection and isolation of bacteria. In its laboratories, it already collects more than thirty strains, isolated in the same place of contamination and treated with FOXWATER selection technology, so that they have a high ability to degrade polluting compounds.

The technologies developed at the Biotechnology Center can be applied to industrial effluents from petrochemicals, textiles, the food industry, leachate from landfills, helping companies to meet the ideal disposal standards of the legislation, also saving on treatment costs.

This makes FOXWATER a reference in environmentally sustainable solutions for projects and installations of effluent treatment plants and biotechnology consulting.

SKID Plug and Play

SKID is a term used to refer to a system designed in a personalized way for each situation, that is, according to the needs of each client.

We at FOXWATER have this modeling as a way of delivering our stations, perfect for customers who do not have a physical space or who would need to move/allocate the station to another point in the future.